The core business of Kwant Controls is the design and manufacturing of various types of control units for the electrical remote control of practically all kinds of propulsion and steering devices, such as: traditional main engine/clutch/CPP-FPP shaft lines, tunnel thrusters, azimuthal thrusters, rudders and water jets.

Products

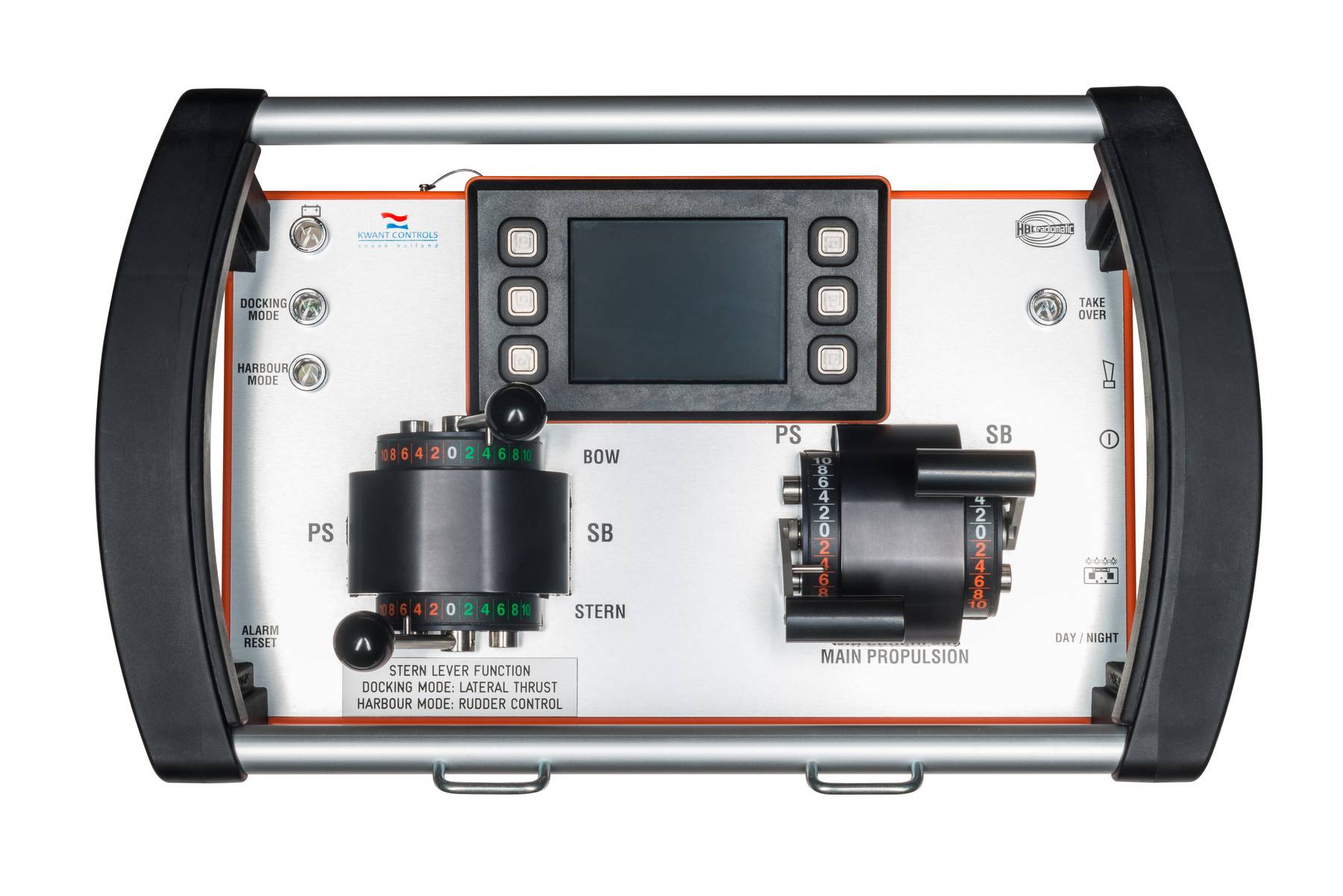

Portable Wireless Control – Spectrum 3

The wireless portable remote control system is a smart and convenient alternative for fixed additional control stands, thus replacing e.g. bridge wing or fly bridge consoles. Saving considerably on building costs & mounting space. It comes with a back-up cable of 20m length that can be simply plugged in on transmitter- and receiver sides, as alternative forthe wireless transmission .

The system is suitable for:

- Propulsion control: Engine RPM, Propeller pitch.

- Steering control: Rudders, Azimuthal thrusters.

- Thruster control: Tunnel thruster RPM, retractable.

- Joystick operation.

Specs

- DECT based wireless technology, providing 240 channels. Automatic selection of free channel. DECT communication is a registered system only accessible for authorized participants.

- Unique worldwide address coding to identify transmitter / receiver combination.

- Redundant diversity control by 2 processors each for transmitter and receiver.

- Engine alarm lead to vibration of the portable transmitter and generates an acoustic signal while displaying the specific alarm.

- Presentation of battery status + pre announcing of empty battery.

- Presentation of RSSI radio signal strength indication.

- Out of range or excessive tilting will activate alarm at the Wheelhouse and will set signals to “zero”.

- Emergency stop button sets signals to “zero” and activates alarm at the Bridge.

- Control can be taken over at the Wheelhouse any time.

- Portable take over only allowed with all controls in neutral position.

- Power supply receiver 10-30VDC.

- Power supply portable transmitter with NIMH rechargeable battery (operating time approx. 20 hrs continuous operation).

- Spare battery and battery charger included.

The wireless remote control system is approved by DNV-GL and LRS.

Options

- Presentation of shaft rpm, Rudder, thrusters position and relevant engine alarms on an LCD display by means of analogue or digital (bar graph) indication.

- Interface between receiver and propulsion / steering systems:

- Analogue signals e.g. 4-20mA or 0-10VDC;

- Digital inputs/outputs;

- CAN-Bus / Profibus / device net, RS232 or RS 485.

- Different sizes and control units configuration available

- Receiver with integrated or external active antenna with data cable (L = 5-50m).

Next

Electronic dimmers

Related Products

PMA-96

The PMA-96 is the high-end angle controller that allows for driving any angle transmitter, usually a potentiometer. Main applications are rudder- and transverse thruster control. It has a bow-shaped rotatable top section, made of black anodized aluminium .

Show details

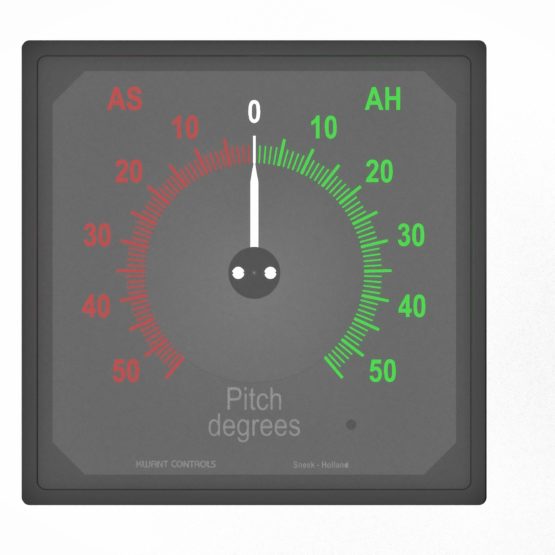

ISI-series, general purpose

The general purpose indicators of the ISI (Isolated Signal Indicators) series have been designed for various applications and offer the advantage of galvanic separation of the input signal and the supply voltage, thus preventing ground loop problems. The series is based on the DC servomotor principle and require an external 4-20mA signal source as well as a 24VDC supply voltage. The 24VDC LED dial illumination can be dimmed externally.

Show details

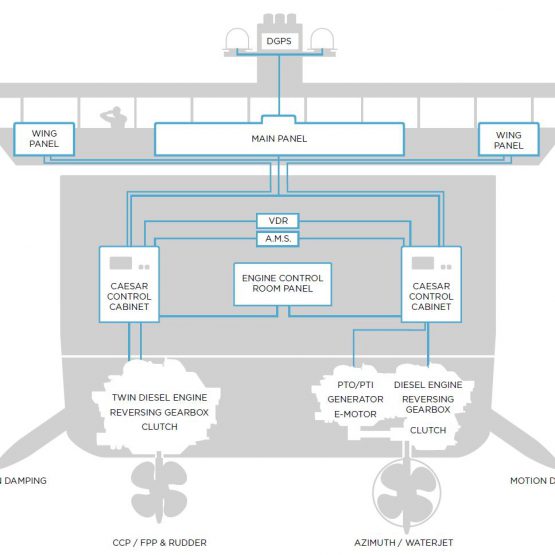

CAESAR Propulsion Control Systems

The CAESAR range of hardware and software modules are dedicated to the control of ship surge, sway and yaw motions, as well as roll and pitch damping. The modules are designed to interface with a broad range of devices and prime movers for propulsion, steering and motion damping.

The CAESAR modules are configured in accordance with the customer needs, ranging from a single device to the full integration of all devices across the entire vessel. This enables control of a wide range of vessels. The high degree of adaptability to the mechanical design of the devices makes the CAESAR system well suitable for both retrofits and new building. Basic configurations of modules are available for the following ship’s devices:

Show details

- CAESAR for typical CPP vessels propelled by controllable pitch propellers and steered by rudders with transverse thrust devices and flaps for roll damping.

- CAESAR for typical FPP vessels propelled by fixed pitch propellers and steered by rudders with transverse thrust devices and flaps for roll damping.

- CAESAR for Azimuth vessels propelled and steered by steerable thrusters with transverse thrust devices.

- CAESAR for high-speed crafts with waterjets and motion damping devices, such as T-foils and trim-tabs.

- Achieving a high operational availability.

- Minimising the costs of fuel and emission.

- Ease of system adjustment and installation.

- Intuitive remote control, via displays and haptics, to ease the crew tasks.

- Remote control lever(s) & tillers for setting the thrust and /or steering demands

- Pushbuttons / indication lamps or jog-switches, for station-in-control transfer, mode selection, clutch-control, hydraulic pump control or NFU back-up control.

- Displays for human-machine interfaces.

R/I converters

These DIN rail mounted electronic modules have been designed to convert the position of a remote control (RC) potentiometer into industry standard 4-20mA current signals. The RC potentiometers are an integrated part of all Kwant Controls control units.

Show details

BUK-C

The BUK-C is the second largest console mounted propulsion control lever unit of the BUK-series, with a well-recognized, widely applied and much appreciated timeless classic appearance. The lever unit comes in a number of variations for user- and machinery interfaces. In the BUK-C extended version, a maximum of four HMI pushbuttons/buzzers/signal lamps/dimmers can be incorporated, as well as a wide range of electrical machinery interfaces. The BUK-C special version, is typically suitable for transverse thruster control.

Show details

CAN RC transmitter module

The CAN RC Transmitter Module reads CAN lever information (e.g. speed or azimuth) on the CANbus and converts this information to current level settings of the 2 DAC outputs.

The device offers flexibility of application with 4 predefined modes of operation for speed and 1 mode of operation for azimuth. All modes have configurable parameters that define the transfer functions for speed and azimuth. The device also allows for configuration via the CANbus in order to get more complex configuration of up to 12 points.

Show details

Steering Wheel

The Kwant Controls steering wheel is in fact a special type of the PMA potentiometer drive, dedicated to adjusting the ship’s heading.

The material of the wheel is usually transparently varnished wood, a finish in black paint is optionally available. The diameter of the hand wheel is 250mm, the base plate comes in 3 variants: 144x144, 192x192 or 270x270mm.

Show details

BUK-H

The BUK-H has been designed with a zero build-in depth, for the desktop mounted shape with potentiometers. It is also suitable for transverse thruster control due to its symmetrical and therefore applicable in various orientations. The basic signal transmitters are dual 5KOhm potentiometers that return 10-90% of the supply voltage over the full lever travel of 120°.

Show details

Electronic dimmers

The Kwant Controls electronic dimmers of the ED-series yield an output voltage almost independent from the load current. This is a great advantage compared to the traditional solution using a power potentiometer.

They have two galvanically isolated circuits that are suitable for systems supplied by 24VDC and are each protected by an internal fuse.

Show details

Integrated telegraph system

The control units of the types BUK-B, BUK-C and Pointer WD can be supplied with an analogue integrated emergency telegraph system of the ‘pointer’ type. The BUK-B in the twin lever execution can be equipped with twin pointer telegraph systems, whereas the BUK-C only has room for a single system. The pointer telegraph is a communication system designed to send orders from the bridge or bridge annexes to the engine room or engine control room. Whenever a new command is being issued, the telegraph alarm will be switched on. In order to mute the alarm, the command must be acknowledged at the selected position by moving the control lever to the position requested.

Precision potentiometers are used to transmit the orders. DC servo motors (RSM4) are used for moving the pointers along the scales of the control units. The system can be switched from telegraph mode to Remote Control (RC) mode by means of a single contact. In RC mode, the telegraph alarm is disabled. The wheelhouse unit’s reply pointer is now connected to its own command lever. RC mode is used to control the main engine directly from the wheelhouse by means of signal transmitters e.g. a potentiometer or 4-20mA module.

Show details